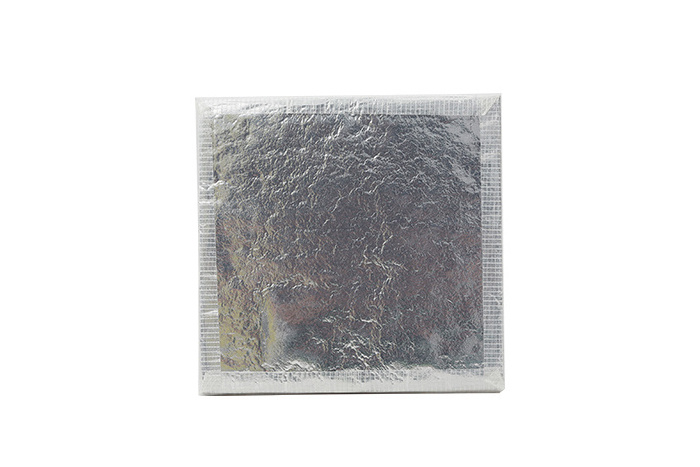

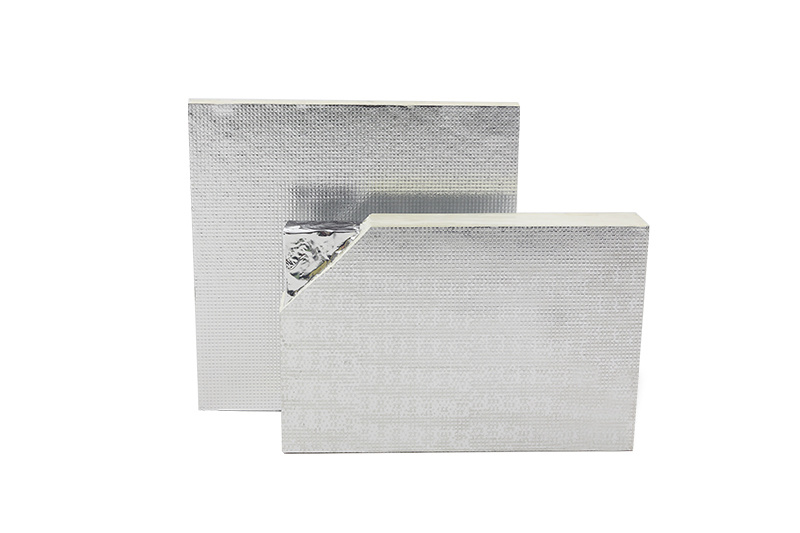

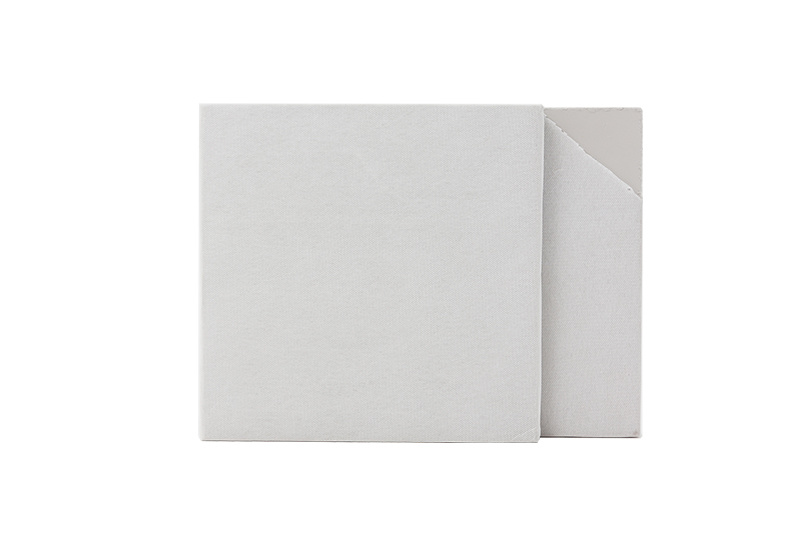

Microporous Insulation Panel

METHERM® M1000 series products are microporous insulation panel) with extremely low thermal conductivity and excellent mechanical properties. The formulation is an opacified blend of reinforced filament fumed(pyrogenic) silica. The maximum application temperature of the M1000 series can reach 1100℃. The thermal insulation performance of the microporous insulation panels is several times better than the best ceramic fiber board and calcium silicate board, especially at higher temperatures.

Advantages of METHERM® Microporous Insulation Panel

Energy saving and better heat retention

Reducing both weight and insulation volume

Increasing effective volume of Insulation objects

The lowest thermal conductivity under high temperature

Low linear shrinkage

Non-combustible

Insensitive to thermal shock

Environmentally friendly and non-toxic, without harmful inhalable fibers

Easy to process (cutting, drilling, etc.) and installation

Resistant to most chemicals

Technical Data

|

Product Model |

M 1000 |

M 1000 Max |

M 1100 |

|

Max. Application Temperature (℃) |

1000 |

1000 |

1100 |

|

Shrinkage Value |

~ 1.5% (900℃, 12 hours) |

~ 0.8% (900℃, 12 hours) |

~ 1.5% (1000℃ 12 hours) |

|

Flexural Strength (Mpa=N/mm²) |

0.12 |

0.13 |

0.12 |

| Compressive Strength at 10% deformation | 0.3MPa | 0.3MPa | 0.3MPa |

|

Fire Protection Class DIN ISO 4102 |

A1 |

A1 |

A1 |

|

Specific Heat Capacity(KJ/kg K) |

~0.9 |

~0.9 |

~0.9 |

|

Thermal Conductivity |

W/m.k |

W/m.k |

W/m.k |

|

20℃ |

0.020 |

0.020 |

0.021 |

|

200℃ |

0.022 |

0.022 |

0.024 |

|

400℃ |

0.025 |

0.025 |

0.028 |

|

800℃ |

0.035 |

0.033 |

0.040 |

|

|

|

Keywords:

Microporous Insulation Panel

Related Products

There is no relevant data for the time being, please add it backstage!

MEVAC® fumed silica vacuum insulation panel(VIP) , is a new type of thermal insulation solution, combined with nano-microporous technology and vacuum technology with thermal conductivity less than 0.0045W/(m·K) and insulation performance up to 5-10 times that of conventional insulation material, which can help you to meet a very high thermal requirement, therefore, is considered the next generation of insulation products. The typical fields of applications are cold chain packaging and construction insulation.

MEVAC® glass fiber vacuum insulation panel is based on glass fiber core material, a new energy-efficient and cost-effective insulation material made of three major parts: glass fiber core material, getter material/desiccant and high barrier lamination. With an excellent initial thermal conductivity of lower than 0.0020 W/m·K, the thermal resistance of our vacuum insulation panel based on glass fiber core material is 10-25 times higher than conventional insulation material and even more. Furthermore, compared with traditional PU insulation materials, energy-saving, cost-effective and environment-friendly vacuum insulation panel contains no ODS (ozone depleting substances) in its manufacturing process and has been widely applying to thermal insulation products such as refrigerators, freezers, refrigerated trucks, cold storages, cold chain shipping containers/boxes, ice storage tanks, etc.

MEVAC® polyurethane foam vacuum insulation panel(PUF-VIP) is composed of glass fiber vacuum insulation core and PU foam coating, which is an innovative insulation material with a moldable appearance, thermal insulation properties and high resistance to mechanical damage. Compared with glass fiber vacuum insulation panel, PUF-VIP with the ease of installation and use has smoother surfaces , edges and corners for the better protection of the glass fiber vacuum insulation panel core material.

MEVAC® M200 fumed silica core is a high performance nano-microporous insulation material mainly made of fumed silica, which is suitable for insulation in medium to low temperature environments. Vacuum insulation panel(VIP) made of M200 fumed silica core material is able to reach an extremely low thermal conductivity less than 0.0045W/m·K, standing out one of the best insulation materials at present.