Steel Industry

METHERM® MIP(Microporous Insulation Panel) used for steel industry (ladles, tundish, steel forging furnaces, reheating furnaces, soaking pit covers) provides the following benefits:

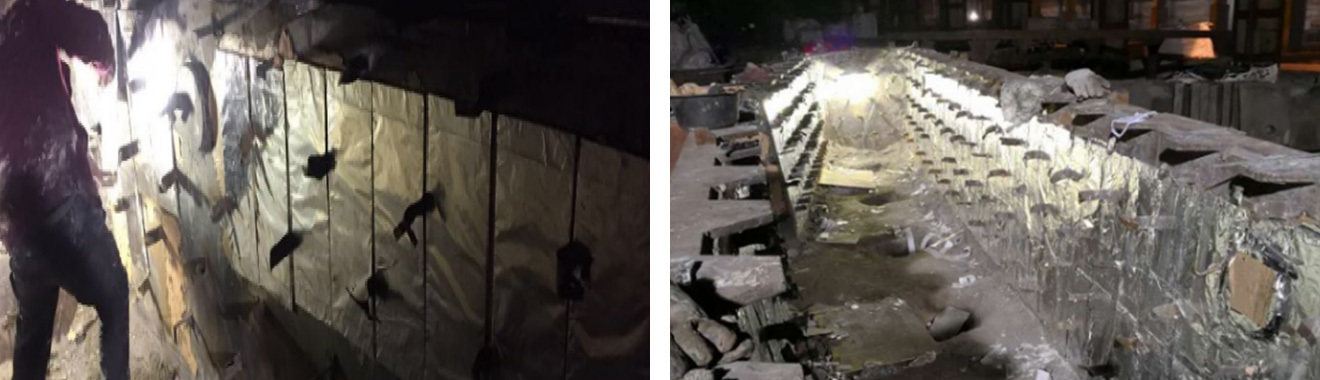

FOR STEEL LADLES

Safety Benefits

The high heat flux of the lining system causes the temperature of the ladle shell to be too high, which damages the strength and creep resistance of the ladle shell. Beneficial for improving the service life of the ladle.

Low shrinkage rate - reduces the probability and risk of gaps and lining cracks.

Production Quality Benefits

Overheating has an impact on the quality of steel billets (segregation, etc.), especially when the water temperature of round billet steel decreases. The use of MIP is beneficial can achievie low superheat pouring, stable steel temperature, and prolonging argon blowing time, which is beneficial for improving steel quality.

Clean steel: Extending the argon blowing time and residence waiting time is beneficial for the homogenization of the internal structure, composition, and temperature of the molten steel, as well as for the full floating of inclusions and gases, and for improving the purity of the molten steel.

Research has shown that the lifespan of refractory materials is a function of the highest temperature during steelmaking blowing, and when maintained at 1700 ℃ for too long, the lifespan of refractory materials will be reduced. If the maximum temperature increases by 10 ℃, the refractory life will decrease by 30%. Reducing the temperature difference between the hot and cold surfaces of the ladle refractory material is beneficial for improving the service life of the refractory material.

Energy Consumption Benefits

The heat dissipation of the ladle is fast, the heat loss of the ladle is large, the temperature drop of the molten steel is large, and low temperature steel is prone to occur. Currently, increasing the tapping temperature or compensating through refining and warming up is used, resulting in prolonged smelting time and significant consumption of energy and raw materials.

It can significantly increase the temperature of the inner wall of the ladle, reduce the online baking time of the ladle, and save energy.

Provide baking efficiency and save energy.

Efficiency Improvement

Expansion: It can improve the lining structure of the ladle, reduce the thickness of the insulation layer, significantly increase the effective capacity of the ladle, and effectively prevent slag and steel overflow.

Smooth pouring and accelerated pace: Thin strip pouring takes a long time and requires high insulation requirements; Shortening the heating time of the LF furnace is beneficial for production organization, accelerating production pace, and increasing output.

FOR THE TUNDISHES

Improve Baking Efficiency And Save Energy

Reduce the temperature drop level from stopping drying to starting pouring, and lower the risk of thermal shock in the lining refractory material.

Reduce the heat storage of refractory lining materials during the initial pouring stage to lower the failure rate of pouring.

Can help reduce overheating, lower overheating for steelmaking, save refining time, and improve steel slab quality.

From The Perspective Of Safety And Health

Reduce steel shell issues, ensure safety, and improve the working environment for continuous casting workers in hot weather, avoiding problems such as rheumatism caused by cooling cladding blowing.

Unlike traditional fibers, it is harmless to human health.

Low shrinkage rate ensure safety.